Overview of DOT Medical Waste Regulations

The U.S. Department of Transportation (DOT) provides specific medical waste regulations which outline how generators of these materials share joint and several liabilities with their waste service provider. Per federal law, all generators of hazardous wastes, including medical wastes, maintain some level of liability for their wastes throughout the transportation, treatment, and disposal process per DOT medical waste regulations. Whether or not you may ever bear responsibilities for transporting medical wastes generated at your practice, it is important that you have some understandings of the liabilities and compliance requirements established in DOT medical waste regulations.

The extended liability from medical wastes is largely tied to the Resource Conservation and Recovery Act (RCRA) which was passed in 1976. This bill was implemented to address the growing concerns of hazardous material and solid waste disposal in the United States at the time and continues to exist as one of the Environmental Protection Agency’s most comprehensive pieces of legislation. Due to the “Cradle to Grave” liabilities established for hazardous waste generators through this legislation along with the Act’s subsequent incorporation into to the responsibilities managed by many other public agencies, including the DOT, it is of importance to work with a service provider that can help reduce risks and protect your reputation through both a understanding of and adherence to the regulations associated with the medical waste stream.

While RCRA legislation has played a significant role in shaping the medical waste industry, this post has been written for the benefit of our customers to provide an overview of the specific regulations involving medical wastes managed by the DOT.

DOT medical waste regulations regarding the handling, packaging, transportation, and training requirements for individuals involved with hazardous materials, including medical wastes, can be found in Title 49 of the Code of Federal Regulations (CFR). Within this Title, hazardous and otherwise dangerous materials are defined into nine separate classifications based on the risks that each of these materials present. Within each class, there are numerous divisions which define the materials more specifically. Title 49 is comprehensive and this post has been organized to relay some of the specifics and how they apply to medical waste.

Defining Medical Waste Through DOT’s Classification

According to the DOT’s classification system, regulated medical waste is documented as a Class 6 (Poisonous or Toxic), Division 2 (Infectious) hazardous material. 49 CFR 173.134 provides the definition and sub-classification criteria for this specific hazardous material:

(1)Division 6.2 (Infectious substance) means a material known or reasonably expected to contain a pathogen. A pathogen is a microorganism (including bacteria, viruses, rickettsiae, parasites, fungi) or other agent, such as a proteinaceous infectious particle (prion), that can cause disease in humans or animals. An infectious substance must be assigned the identification number UN 2814, UN 2900, UN 3373, or UN 3291 as appropriate, and must be assigned to one of the following categories:

(i)Category A: An infectious substance in a form capable of causing permanent disability or life-threatening or fatal disease in otherwise healthy humans or animals when exposure to it occurs. An exposure occurs when an infectious substance is released outside of its protective packaging, resulting in physical contact with humans or animals. A Category A infectious substance must be assigned to identification number UN 2814 or UN 2900, as appropriate. Assignment to UN 2814 or UN 2900 must be based on the known medical history or symptoms of the source patient or animal, endemic local conditions, or professional judgment concerning the individual circumstances of the source human or animal. [Note: Entech does not accept Category A wastes]

(ii)Category B: An infectious substance that is not in a form generally capable of causing permanent disability or life-threatening or fatal disease in otherwise healthy humans or animals when exposure to it occurs. This includes Category B infectious substances transported for diagnostic or investigational purposes. A Category B infectious substance must be described as “Biological substance, Category B” and assigned identification number UN 3373. This does not include regulated medical waste, which must be assigned identification number UN 3291.

With this definition understood, further information regarding the packaging and transportation requirements can be found in the DOT’s Hazardous Material Table (49 CFR 172.101). In regards to proper packaging and transportation, the next step in this process is to determine whether the material is enclosed in bulk or non-bulk packaging as defined by DOT.

Because post has been written for the benefit of our customers and the requirements most applicable to their facilities, we will limit the discussion to non-bulk packaging which would incorporate any of Entech’s containers that would be utilized at any particular customer location. Let’s further assume that we are considering Division 6.2 material classified as UN 3291, Regulated Medical Waste n.o.s. (not otherwise specified) as the material that will be generated at your facility.

Packaging Requirements

49 CFR 173.24 and 49 CFR 173.134 provide information on the specific requirements of non-bulk packaging. Medical waste prepared for non-bulk transportation must be prepared for shipment in containers that meet the structural and design requirements of Packing Group II with a DOT shipping name of “Regulated Medical Waste n.o.s. UN 3291”. Generally, the packaging utilized for regulated medical waste according to DOT medical waste regulations is described in 49 CFR 173.24 which states that:

Each package used for the shipment of hazardous materials under this subchapter shall be designed, constructed, maintained, filled, its contents so limited, and closed, so that under conditions normally incident to transportation –

(1) Except as otherwise provided in this subchapter, there will be no identifiable (without the use of instruments) release of hazardous materials to the environment

More specifically, the requirements for medical waste non-bulk packaging are further defined in 49 CFR 173.197. This section communicates that containers used for the transportation of medical waste must have the following characteristics and be:

- Rigid;

- Leak resistant;

- Impervious to moisture;

- Of sufficient strength to prevent tearing or bursting under normal conditions of use and handling;

- Sealed to prevent leakage during transport;

- Puncture resistant for sharps and sharps with residual fluids;

- Break resistant and tightly lidded or stoppered for fluids in quantities greater than 20 cubic centimeters.

- Visually communicate a hazard warning, the DOT shipping name, and identification number

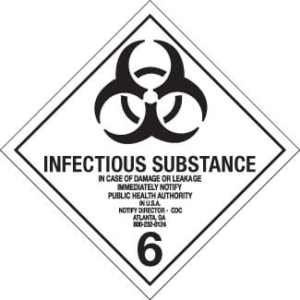

Finally, non-bulk containers are also subjected to certain labeling requirements consistent with the rules and regulations associated with all other DOT classified hazardous materials. Regulated medical waste, specifically the Class 6, Division 6.2 UN 3291 material discussed in this post, also has some exceptions in regards to labeling requirements. Typically, packaging for DOT classified hazardous materials must display the square on point signage that is specific to each hazard class. For medical waste, the exception to this labeling requirement which allows for a substitution from the typical square on point labels is noted in 49 CFR 173.134:

(1) A regulated medical waste transported by a private or contract carrier is excepted from –

(i) The requirement for an “INFECTIOUS SUBSTANCE” label if the outer packaging is marked with a “BIOHAZARD” marking in accordance with 29 CFR 1910.1030; and

(ii) The specific packaging requirements of § 173.197, if packaged in a rigid non-bulk packaging conforming to the general packaging requirements of §§ 173.24 and 173.24a and packaging requirements specified in 29 CFR 1910.1030, provided the material does not include a waste concentrated stock culture of an infectious substance. Sharps containers must be securely closed to prevent leaks or punctures.

Division 6.2 DOT Square on Point Label

OSHA Biohazard Icon (29 CFR 1910.1030(g)(1))

While these packaging requirements are largely managed by service providers and the companies that manufacture containers appropriate for these wastes, it remains important for generators to have some understanding of these regulations. Per federal law, the entities supplying wastes (i.e. generators) retain responsibilities for ensuring that the packaging used for the transportation of their medical wastes adheres to all DOT medical waste regulations as noted in 49 CFR 173.24:

(1) Even though certain packagings are specified in this part, it is, nevertheless, the responsibility of the person offering a hazardous material for transportation to ensure that such packagings are compatible with their lading.

Entech utilizes reusable plastic containers for its medical waste collection and transportation services. All of Envirolaka’s offered containers for the collection and transportation of medical waste are DOT, OSHA, and FDA approved. If you are unsure how or if your medical waste packaging meets DOT medical waste regulations, you should ask your service provider.

Transportation Requirements

As one may expect, DOT medical waste regulations for the actual transportation of medical wastes represent the bulk of applicable regulations and apply largely to the companies responsible for providing this transportation service. Nonetheless, there are general provisions which further reiterate the shared responsibilities between your provider and your practice included in 49 CFR 171.2:

(c) Each person who performs a function covered by or having an effect on a specification or activity prescribed in part 178, 179, or 180 of this subchapter, an approval issued under this subchapter, or an exemption or special permit issued under subchapter A of this chapter, must perform the function in accordance with that specification, approval, an exemption or special permit, as appropriate.

(e) No person may offer or accept a hazardous material for transportation in commerce unless the hazardous material is properly classed, described, packaged, marked, labeled, and in condition for shipment as required or authorized by applicable requirements of this subchapter or an exemption or special permit, approval, or registration issued under this subchapter or subchapter A of this chapter.

Once wastes are prepared for shipment (legally, this preparation is the responsibility of the generator or ‘offeror’), they are ready for transport by a permitted waste hauler. Transporters of medical waste must maintain appropriate registrations by the USDOT through the Pipeline and Hazardous Material Safety Administration (PHMSA) and in some instances state transportation offices. Legally, generators may transport their own medical wastes without permit only if the total weight of transported material is less than 25 lbs.

Generator’s DOT medical waste regulations associated with transportation are largely related to the manifest process which documents both the transportation and treatment of shipped waste. As part of this process, declarations are made as the to the specific materials generators are transferring to service providers which is transported and ultimately processed into non-infectious material. These manifests are utilized as a means to track hazardous wastes throughout the “Cradle to Grave” timeline.

Hazardous waste manifests also represent another connection between the numerous agencies responsible for managing medical wastes including the DOT, the EPA, and state regulators. More information on the hazardous waste manifest system can be found on the EPA’s website. This system was heavily influenced through the Medical Waste Tracking Act established in 1988. This legislation expired in 1991, but can be considered as a driving force behind the creation of the medical waste industry.

Today, the monitoring and tracking of medical waste from the point of generation to ultimate disposal in an approved landfill facility has been passed from the EPA to individual state jurisdiction. Each state either adheres to previously established federal guidelines or enacts its own specific regulations so long as they are more restrictive than federal law.

According to federal statue as defined in 49 CFR 172.202 manifest shipping papers must include the following (some of this information is also required to be displayed on the packaging itself):

- Material Identification Numbers (i.e. UN 3291)

- Proper Shipping Name of Material (i.e. Regulated Medical Waste, n.o.s.)

- Hazard Class Identification (i.e. 6.2)

- Packaging Group (i.e. PG II)

- Total Quantity of Waste Shipped (i.e. Lbs, Gallons, Containers, Cubic Feet, etc.)

While medical waste services providers general prepare and provide appropriate manifests for the transportation of wastes, generators are legally required to document that all information included on manifests is accurate through their signature. This signature confirmation is required by law, outlined in 49 CFR 172.204, and included on each transportation manifest for generators to provide confirmation of the following:

(2) “I hereby declare that the contents of this consignment are fully and accurately described above by the proper shipping name, and are classified, packaged, marked and labeled/placarded, and are in all respects in proper condition for transport according to applicable international and national governmental regulations.”

Throughout the medical waste industry, transportation manifests have historically been produced in carbon copy format so that additional records can be added and passed to appropriate parties as wastes are transferred and ultimately processed. Per federal law, these records must be maintained by hazardous waste generators for a period of three years per DOT medical waste regulations.

In efforts to improve the visibility of Alaska’s medical waste stream among our customers, regulators, and our operations, Entech maintains an electronic manifest system that is capable of managing these documents through a database system. By comparison to the traditional paper-based and carbon copy method, this digital process provides improved transparency and record management capabilities that are to the benefit of all involved. No more binders, lost records, or general headaches trying to understand the volumes and costs associated with medical waste disposal services or hours spent managing the paper flows of matching transportation records to processing records to invoices when the need arises.

At Entech, customers maintain access to all of their transportation and treatment manifests through a secure online portal which provides 24/7 access to this information. Entech is the only medical waste service provider in Alaska to offer this capability. More information about our waste management system can be found here.

Training Requirements

DOT maintains specific training (and retraining) requirements for employees who have some involvement with the transportation of medical waste. Information on these requirements can be found in 49 CFR 172.700 and associated sub-parts along with the presentation linked here. While it may seem obvious that these requirements extend to the service providers transporting your medical waste, many generators are unaware that they too have training requirements through the DOT due to their role as a generator of hazardous wastes and their involvement with the manifest process.

Any individual who may be involved with preparing or transporting hazardous materials, including the individuals who prepare packages for transport or sign off on manifests for medical wastes, is required to have training. Per regulation, training should be completed by employees involved with hazardous wastes within 90 days of their hire date and must be retaken every three years.

It is the employer’s responsibility to fully comply with the training requirements and failure to train employees can result in penalties. This is an easily avoidable compliance issue which can be satisfied through through completion of DOT HM-181 training.

As part of Entech’s compliance solutions, all customers have access to HM-181 training. This training, and our compliance portal, is made available to our customers free of charge to help ensure that all who are involved in the waste management process are knowledgeable, safe, and compliant. We are the only service provider in the State of Alaska offering this complementary solution.

Penalties and Fines

While this post has been created to provide an overview of the DOT medical waste regulations, we hope that the information can help generally improve safety and compliance at your practice. By simply acknowledging and adhering to the regulations that are in place, we all stand to benefit from improved public health and safety.

Non-compliance fines associated with DOT regulations can be found in 49 CFR 107.329:

(a) A person who knowingly violates a requirement of the Federal hazardous material transportation law, an order issued thereunder, this subchapter, subchapter C of the chapter, or a special permit or approval issued under this subchapter applicable to the transportation of hazardous materials or the causing of them to be transported or shipped is liable for a civil penalty of not more than $77,114 for each violation, except the maximum civil penalty is $179,933 if the violation results in death, serious illness or severe injury to any person or substantial destruction of property. There is no minimum civil penalty, except for a minimum civil penalty of $463 for violations relating to training. When the violation is a continuing one, each day of the violation constitutes a separate offense.

Entech exceeds all federal, state, and local regulatory requirements associated with the management of medical wastes including those applicable through DOT medical waste regulations. If we can help answer any compliance questions you may have, please contact us.